The challenge: Make it makeable

ONI Bio challenged Gener8 to make their super resolution biological microscope more manufacturable. They loved the existing design but it was made from a solid block of machined aluminum that was held together with over 40 screws and black anodized. The result was beautiful but extremely expensive and had high scrap rates.

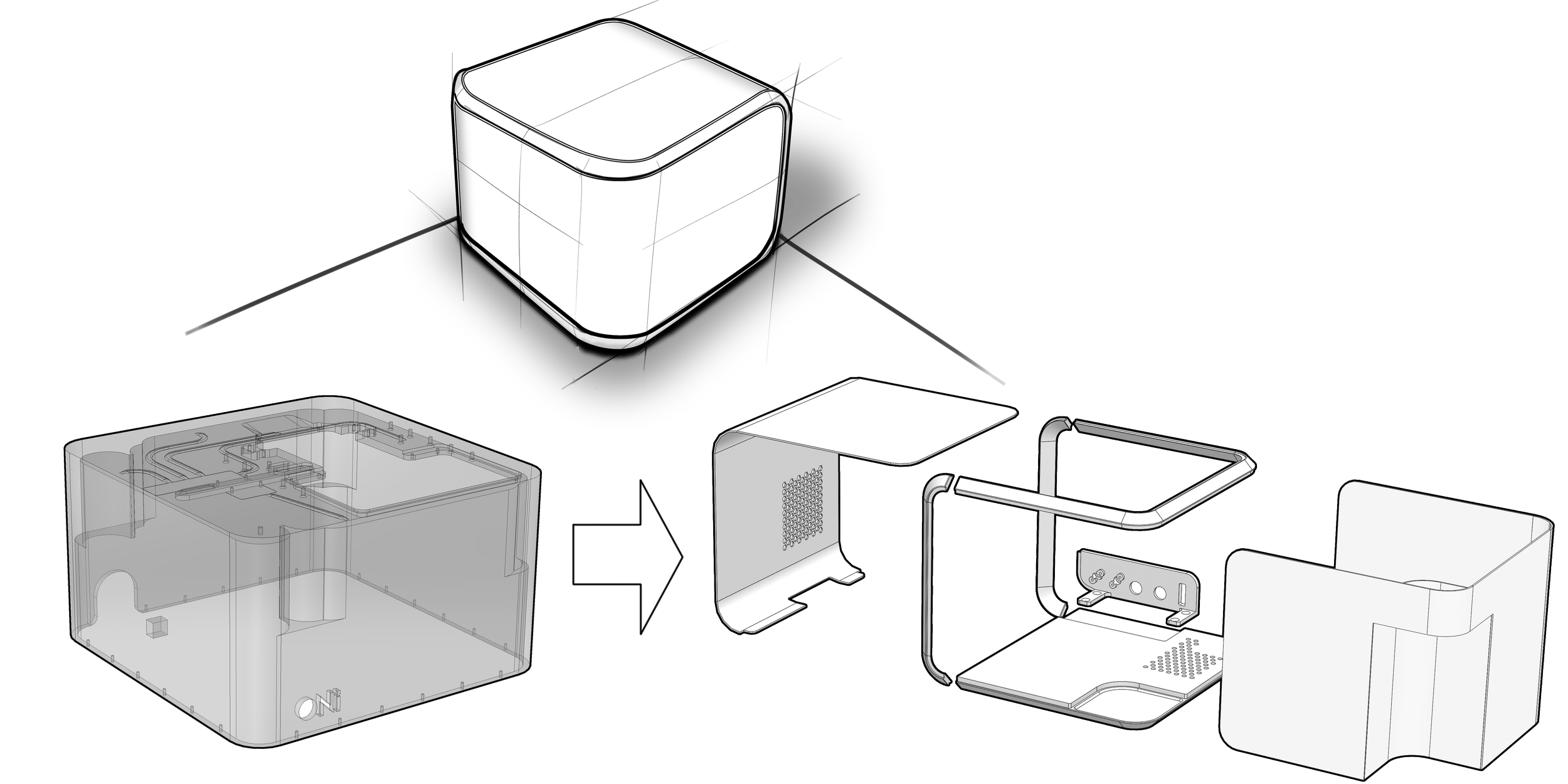

I replaced the solid block aluminum with powder coated sheet metal, held together with a machined exoskeleton frame. This frame held the sheet metal pieces in precise alignment and doubled as a decorative element that still had the high-end machined aluminum look but at a much lower cost.

From Unmakeable To Makeable

The Result: A manufacturable family look

Collaborating with ONI, Gener8 engineering and their manufacturers, we applied my design language to their entire product family. This design and method of manufacture is still in use today. Rendering by Justin Francke.